if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Cooler Master Nepton 280L Liquid CPU Cooler Review

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

By Tom Jaskulka

Manufacturer: Cooler Master Ltd., Inc.

Product Name: Nepton 280L

Model Number: RL-N28L-20PK-R1

UPC: 884102025150

Price As Tested: $139.99 (Newegg / Amazon)

Full Disclosure: The product sample used in this article has been provided by Cooler Master.

The 280mm closed-loop all-in-one liquid cooling selection is about to grow by one: The Cooler Master (RL-N28L-20PK-R1) Nepton 280L. Sporting new dual 140mm JetFlo fans with POM bearings and a new pump design with LED, the 280L is Cooler Master’s answer to the Kraken X60 and H110. Will an all-new pump, high-flow fans and a 280mm radiator be enough to take on the competition? Benchmark Reviews will find out if the Nepton 280L can handle an overclocked FX platform and see how it stacks up against the competition.

Cooler Master also sent along two of their new 120mm JetFlo fans (140mm JetFlo fans are included with the Nepton 280L) containing their new POM bearings, most recently tested by Benchmark Reviews with the Cooler Master V8 GTS. We’ll take a closer look at what makes these fans different and test them on the Nepton 280L as well.

Features & Specifications

| Model | RL-N28L-20PK-R1 |

| CPU Socket | Intel LGA 2011 / 1366 / 1150 /1155 / 1156 / 775 AMD Socket FM2 / FM1 / AM3+ / AM3 / AM2 |

| Dimension | 75 x 69.8 x 49.1 mm ( 3 x 2.7 x 1.9 inch ) |

| Radiator Dimensions | 311 x 139 x 30 mm ( 12.2 x 5.5 x 1.2 inch ) |

| Radiator Material | Aluminum |

| Fan Dimension | 140 x 140 x 25 mm ( 5.9 x 5.9 x 1 inch ) |

| Fan Speed | 800~2000 RPM (PWM) ± 10% |

| Fan Airflow | 54~122.5 CFM ± 10% |

| Fan Air Pressure | 0.7~3.5 mm H2O ± 10% |

| Fan Life Expectancy | 40,000 hours |

| Fan Noise Level (dB-A) | 21~39 dBA |

| Bearing Type | Rifle bearing |

| Connector | 4-Pin |

| Fan Rated Voltage | 12 VDC |

| Fan Rated Current | 0.3A |

| Power consumption | 3.6W |

| Pump Life Expectancy | 70,000 hrs |

| Pump Noise Level | <25 dBA |

| Pump Rated Voltage | 12 VDC |

| Pump Power Consumption | 2.9W |

| Compatibility | Top: Cosmos II, Cosmos SE, HAF XM, Trooper Front: Cosmos SE, HAF XB |

| Warranty | 2 years |

| UPC Code | 884102025150 |

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Closer Look: Nepton 280L

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Using the same packaging that exists on all of Cooler Master’s new products, the Nepton 280L sits snug inside a cardboard insert similar to almost every liquid cooling unit on the market.

With each component wrapped individually, the Nepton 280L contains the radiator attached to the new pump with large-diameter FEP flex tubing, the two 140mm JetFlo fans, mounting hardware and an instruction booklet.

Cooler Master includes everything you’ll need for every socket on the market. Mainstream Intel and AMD sockets will share the universal back plate (that is labeled for easy installation); you just need to select the right pair of brackets to attach the CPU water block – of course, socket 1366/2011 will use the back plate that comes with the motherboard and the included screws. The screws that attach the fans to the radiator (and the radiator to the case) are thumbscrews, making installation refreshingly simple. A PWM splitter cable is included, as well as a small tube of Cooler Master’s thermal interface material.

With an all black motif (and gloss black accents throughout) the Nepton 280L should blend in with almost every design scheme. The only LED present is the illuminated Cooler Master logo on the water block, done in a classy white. I like having some sort of LED on the pump so I can tell at a glance it is connected and receiving power, but even if you’re not a fan of LED accents this one is tastefully done and much more subtle than many LED designs.

The Nepton 280L contains a standard 280mm aluminum radiator, threaded for both 140mm and 120mm fans. This allows a wider range of mounting options but you’ll still need to find a case that can accommodate the 140mm width (total dimensions of the radiator are 311mm x 139mm x 30mm).

Adding the 140mm JetFlo fans adds another 25mm to the “depth” of the entire unit when installed, so make sure your case has 55mm (2.2 inches) of clearance between your mounting point and any hardware close by.

The CPU water block contains a pump of Cooler Master’s design with a claimed cooling capacity of 300W. The cold plate itself is copper and contains new “Ultrafine Microchannel” fins that provide a larger surface area to transfer heat from the copper to the sealed coolant.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Detailed Features: Nepton 280L

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Let’s get to installing the Nepton 280L on the test platform.

The universal back plate is pretty standard, and it has an important installation component that I’ve come to really appreciate. See those black plastic covers on the end of the four AMD mount points? Those are slipped over the posts that extend through the motherboard (and which become the mounting points for the water block) and hold the posts in place.

Even better, the opposite side also uses plastic washers to secure the back plate in place before mounting the water block – making the entire installation process significantly easier. I especially appreciate seeing these, as some water cooling units can be difficult to line up while holding the posts, back plate and the water block simultaneously… Cooler Master’s design keeps half of the installation hands-free so you can concentrate on attaching the water block in as level of an orientation as possible.

The copper cold plate of the Nepton 280L’s water block is ground to a finish that’s about average for coolers; at least it’s flat and smooth enough to keep the application of thermal paste to a normal amount. On top-tier products such as this I would like to see a little extra polish, even though the extra machining required to do so probably isn’t worth the extra degree or two of CPU temperature difference.

The above photo displays the AMD brackets mounted to the water block/pump assembly – simply select which set of brackets you need and attach them to the sides with four screws.

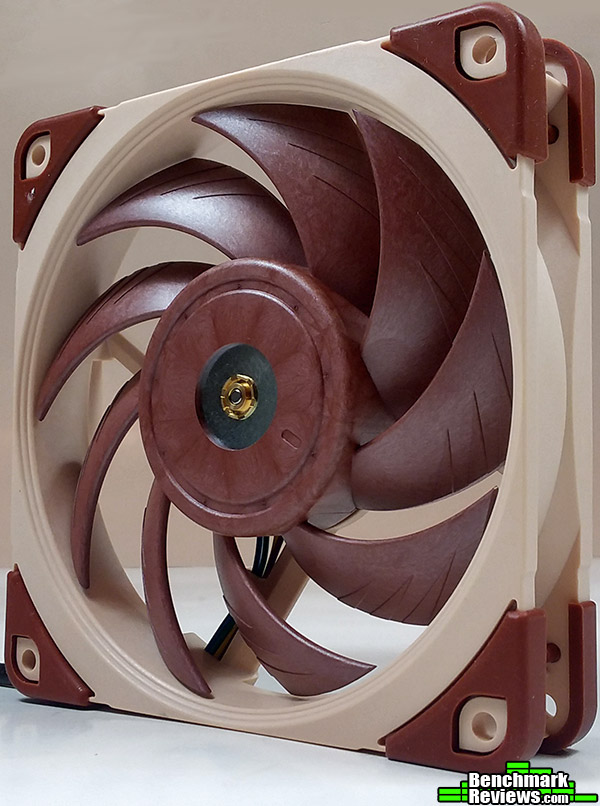

The included 140mm JetFlo fans are a new series of premium fans that use Cooler Master’s POM (PolyOxyMethylene) bearings for extended life and reduced noise characteristics. POM (sold under various brands like Delrin) is a thermoplastic that has high stiffness and some self lubricating properties, so it makes a good material for a fan bearing. We probably don’t have time to test the longevity claims, but the reduced noise profile is instantly appreciated. There isn’t a hint of grinding or whine with these fans while at idle or high speeds, and the rubber pads on the corners help isolate vibrations and dampen any further noise. Don’t be mistaken though: these are powerful fans, and get LOUD when at full RPM (which they shouldn’t hit under normal operation).

The installation of the Nepton 280L went pretty smoothly until it came time to mount the radiator and fans to the chassis. The large diameter FEP tubing is a decent length, but it isn’t long enough to mount the radiator in any other location in a full tower other than the top exhaust. This isn’t necessarily a problem as this is probably one of the most common and preferred configurations of a 280mm cooler, but in the NXZT H630 I use for testing the 140mm fan mounts up top are centered. This means a mounted radiator (and fans) will get pretty close to some motherboard components, and that 8-pin AUX CPU cable is a usual culprit. It’s close, but it does fit – just make sure to plug in that power cable first! The standard depth of the radiator prevents any other mishaps though, and allows the Nepton 280L to fit in most cases that can accommodate twin 140mm fans.

Overall, this was an easy cooling unit to install. I especially appreciate the mounting system as it is one of the least frustrating installs I’ve done for a cooler of this type. Cooler Master continues this theme of usability with the fans, as they attach easily to the radiator through the use of thumbscrews – I’m surprised it has taken this long for someone to start using thumbscrews for this purpose, as they are used for almost every other component at this point. The tradeoff of using thumbscrews is slightly reduced clearance; in locations that have a slide-in or removable dust filter you may need to forgo the use of the thumbscrews to put the filter back in place (the screws will stick up too much otherwise). Cooler Master includes enough thumbscrews for a push/pull configuration if you’d like to add additional fans – just make sure you have the room!

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Cooler Master JetFlo POM Fans

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Speaking of additional fans, Cooler Master sent along a pair of their new 120mm JetFlo series of performance fans. Utilizing a POM bearing just like their larger 140mm counterparts, these JetFlos are rated for 95 CFM of airflow and 2.72mm H2O of air pressure (+/- 10%).

The corners of the 120mm versions are blocks of rubber with a threaded steel insert for attaching them to a case or a cooler. You won’t be able to use standard fan screws with these, but they come with a set of appropriate sized mounting screws. While it may challenge the “standard,” it’s nice to see a properly threaded metal attachment point instead of relying on the end-user to carve a thread in a plastic hole.

The 120mm JetFlos are a 4-pin PWM fan, but they come with two fan speed (voltage, really) limiters to keep RPMs around 1200 or 1600 RPM if you don’t have access to PWM motherboard control or a fan controller.

See? Entire blocks of rubber! The JetFlo series of fans have a definite heft to them, and it gives the assembly an overall feeling of quality which will probably help last the stated life expectancy of 160,000 hours. You’ll also notice that there aren’t any holes for LEDs or wires as the LEDs are contained in the fan hub, which really helps clean up the outside and provides for a nice even glow – no catching a blinding LED at certain angles with this configuration!

The Nepton 280L is obviously designed to fit 140mm fans, but it is drilled to accept 120mm fans as well – here’s what a pair of 120mm JetFlos would look like on a 280mm radiator.

For a size comparison, here are the two JetFlo fans placed next to each other. Incidentally, if you were bothered by the proximity of the 8-pin CPU cable, swapping out a fan for a 120mm version would free up more than enough room…not the best solution of course, but I love having options available!

Since the Nepton 280L comes with thumbscrews for installing the fans, it was simple to swap them out with the radiator already in place. Powered on, the centrally located SMD LEDs illuminate the blades with a very even glow that gives the illusion of an illuminated disc (instead of individual beams of light highlighting the curve of a fan blade). I really prefer this type of effect if I’m opting for illuminated fans, and Cooler Master has JetFlos in various colors (red, white, blue and a non-LED black with smoke-tinted blades – although I’m a little sad to see that green or orange didn’t make the list…). Performance when mounted in place of the 140mm JetFlo fans on the Nepton 280L was pretty impressive, as the maximum core temp reached only increased by 2 degrees Celsius. Of course, this is performance measured relative to 140mm JetFlo fans, it isn’t a very good indicator of absolute performance of the fans specifically. In the next section we’ll compare the cooler to some of the competition, but don’t be afraid to take the time to read through some background information on how we prepare CPU coolers for testing.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

CPU Cooler Heatsink Preparations

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

It bears repeating here that no heat-sink will work effectively unless it transfers heat from the CPU. To do that, it needs to be in contact with the CPU heat spreader or die, with the greater the contact surface the greater the potential for heat transfer. One of our own writers here at Benchmark Reviews has done a lot of work in this area, and it is certainly worth the time it takes to read (and re-read) the discoveries he made during the famous 80+ thermal paste tests (I still see Newegg reviews reference the discoveries made therein).

I mention this because I still see this as a major source of misinformation – most end users will use far too much thermal interface material when switching CPU coolers. Possibly through little fault of their own – I’ve read official repair manuals stating to use the entire tube of thermal paste when replacing a CPU and heat-sink. This is, in almost every case, FAR too much – to the point of being harmful in most cases. So do yourself a favor and get acquainted with CPU Cooler Preparations and Thermal Paste Application.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Contact Surface Preparation

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Processor and CPU cooler surfaces are not perfectly smooth and flat surfaces, and although some surfaces appear polished to the naked eye, under a microscope the imperfections become clearly visible. As a result, when two objects are pressed together, contact is only made between a finite number of points separated by relatively large gaps. Since the actual contact area is reduced by these gaps, they create additional resistance for the transfer of thermal energy (heat). The gasses/fluids filling these gaps may largely influence the total heat flow across the surface, and then have an adverse affect on cooling performance as a result.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Thermal Paste Application

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

The only reason for using Thermal Interface Material is to compensate for flaws in the surface and a lack of high-pressure contact between heat source and cooler, so the sections above are more critical to good performance than the application of TIM itself. This section offers a condensed version of our Best Thermal Paste Application Methods article.

After publishing our Thermal Interface Material articles, many enthusiasts argued that by spreading out the TIM with a latex glove (or finger cover) was not the best way to distribute the interface material. Most answers from both the professional reviewer industry as well as enthusiast community claim that you should use a single drop “about the size of a pea”. If there was ever any real advice that applies to every situation, it would be that thermal paste isn’t meant to separate the two surfaces but rather fill the microscopic pits where metal to metal contact isn’t possible.

After discussing this topic with real industry experts who are much more informed of the process, they offered some specific advice that didn’t appear to be a “one size fits all” answer:

- CPU Cooling products which operate below the ambient room temperature (some Peltier and Thermo-electric coolers for example) should not use silicon-based materials because condensation may occur and accelerate compound separation.

- All “white” style TIM’s exhibit compound breakdown over time due to their thin viscosity and ceramic base (usually beryllium oxide, aluminum nitride and oxide, zinc oxide, and silicon dioxide). These interface materials should not be used from older “stale” stock without first mixing the material very well.

- Thicker carbon and metal-based (usually aluminum-oxide) TIM’s may benefit from several thermal cycles to establish a “cure” period which allows expanding and contracting surfaces to smooth out any inconsistencies and further level the material.

The more we researched this subject, the more we discovered that because there are so many different cooling solutions on the market it becomes impossible to give generalized advice to specific situations. Despite this, there is one single principle that holds true in every condition: Under perfect conditions the contact surfaces between the processor and cooler would be perfectly flat and not contain any microscopic pits, which would allow direct contact of metal on metal without any need for Thermal Interface Material. But since we don’t have perfectly flat surfaces, Thermal Material must fill the tiny imperfections. Still, there’s one rule to recognize: less is more.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Surface Finish Impact

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

CPU coolers primarily depend on two heat transfer methods: conduction and convection. This being the case, we’ll concentrate our attention towards the topic of conduction as it relates to the mating surfaces between a heat source (the processor) and cooler. Because of their density, metals are the best conductors of thermal energy. As density decreases so does conduction, which relegates fluids to be naturally less conductive. So ideally the less fluid between metals, the better heat will transfer between them. Even less conductive than fluid is air, which then also means that you want even less of this between surfaces than fluid. Ultimately, the perfectly flat and well-polished surface is going to be preferred over the rougher and less even surface which required more TIM (fluid) to fill the gaps.

This is important to keep in mind, as the mounting surface of your average processor is relatively flat and smooth but not perfect. Even more important is the surface of your particular CPU cooler, which might range from a polished mirror finish to the absurdly rough or the more complex (such as Heat-Pipe Direct Touch). Surfaces with a mirror finish can always be shined up a little brighter, and rough surfaces can be wet-sanded (lapped) down smooth and later polished, but Heat-pipe Direct Touch coolers require some extra attention.

To sum up this topic of surface finish and its impact on cooling, science teaches us that a smooth flat mating surface is the most ideal for CPU coolers. It is critically important to remove the presence of air from between the surfaces, and that using only enough Thermal Interface Material to fill-in the rough surface pits is going to provide the best results. In a perfect environment, your processor would mate together with the cooler and compress metal on metal with no thermal paste at all; but we don’t live in perfect world and current manufacturing technology cannot provide for this ideal environment.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Mounting Pressure

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Probably one of the most overlooked and disregarded factors involved with properly mounting the cooler onto any processor is the amount of contact pressure applied between the mating surfaces. Compression will often times reduce the amount of thermal compound needed between the cooler and processor, and allow a much larger metal to metal contact area which is more efficient than having fluid weaken the thermal conductance. The greater the contact pressure between elements, the better it will conduct thermal (heat) energy.

Unfortunately, it is often times not possible to get optimal pressure onto the CPU simply because of poor mounting designs used by the cooler manufacturers. Most enthusiasts shriek at the thought of using the push-pin style clips found on Intel’s stock thermal cooling solutions. Although this mounting system is acceptable for casually-used computers, there is still plenty of room for improvement when overclocking.

Generally speaking, you do not want an excessive amount of pressure onto the processor as damage may result. In some cases, such as Heat-pipe Direct Touch technology, the exposed copper rod has been pressed into the metal mounting base and then leveled flat by a grinder. Because of the copper rod walls are made considerably thinner by this process, using a bolt-through mounting system could actually cause heat-pipe rod warping. Improper installation not withstanding, it is more ideal to have a very strong mounting system such as those which use a back plate behind the motherboard and a spring-loaded fastening system for tightening.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Heatpipe Directional Orientation

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Heat-pipe technology uses several methods to wick the cooling liquid away from the cold condensing end and return back towards the heated evaporative end. Sintered heatpipe rods help overcome Earth’s gravitational pull and can return most fluid to its source, but the directional orientation of heatpipe rods can make a significant difference to overall cooling performance.

The following is retained word for word from the source article, but note that not every CPU cooler will be or can be tested in a horizontal orientation. Please refer to the testing methodology on the next page or the pictures in the article to see how each specific cooler was tested.

For the purpose of this article, all CPU-coolers have been orientated horizontally so that heatpipes span from front-to-rear with fans exhausting upward and not top-to-bottom with fans blowing towards the rear of the computer case. This removes some of the gravitational climb necessary for heatpipe fluid working to return to the heatsink base. In one example, the horizontally-mounted tower heatsink cooled to a temperature 3° better than when it was positioned vertically. While this difference may not be considered impressive to some, hardcore performance enthusiasts will want to use every technique available to reach the highest overclock possible.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Testing & Results

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Testing Methodology

The CPU coolers tested were installed in a computer case in its normal, upright orientation (a NZXT H630). A 200mm top/rear exhaust fan was added to the enclosure to aid in cooling VRMs and most of the front drive cages were removed to clear the path from the 200mm intake fan. The GPU remained installed during testing. All fans were set to 100% to remove that variable from the results (motherboard fan control was disabled). In the case of liquid coolers, they were mounted in the rear exhaust location if possible (otherwise, as in the case of the Swiftech H220 and the TD02*, mounted in the “floor” of the H630 as an intake). This is how I would assume most enthusiasts would set up a similar case while overclocking a similar platform.

All tests were performed using the AIDA64 Extreme Edition System Stability test, using 100% fan settings on an Asus M5A99FX PRO R2.0 (PWM/motherboard fan controls were disabled for testing). The test was allowed to run until temperatures plateaued, then I recorded the ambient temperature of the intake air and began logging temperatures over the next minute. After an initial warm-up run, I ran each test at least three times (more if I received inconsistent results), and recorded the ambient temperature again. Once I had “good data,” I dropped the best and worst results and subtracted the (average over the test) ambient temperature from the median result to arrive at the delta T temperature you see in the chart.

Each time a heatsink was swapped, the Tuniq TX-2 thermal interface material I used for each application was cleaned off of the contact surfaces with Arctic Silver’s ArctiClean two-step TIM remover, and an appropriate amount of TX-2 replaced for the next heatsink. Due to the nature of applying TIM and mating two surfaces, I would like to adopt a 3% margin of error – even though my thermometers and the built-in thermal diode measure temperatures down to one-tenth of a degree Celsius, it could be assumed that temperatures within a degree of each other are essentially the same result.

*The SilverStone TD02 was oriented and tested in the same location as the Swiftech H220, but the hoses were not long enough to actually mount the radiator to the chassis.

Test System

-

Motherboard: Asus M5A99FX-PRO R2.0 w/ 1708 BIOS/UEFI

-

System Memory: 8GB (2x4GB) GSkill Ares 1600MHz DDR3 CL8

-

Processor: AMD FX-8320 Piledriver, 4.6GHz/1.428V

-

Audio: On-Board

-

Video: Sapphire Radeon 7950 3GB 1000MHz Core, 1300MHz mem

-

Disk Drive 1: OCZ Vector 240GB

-

Enclosure: NZXT H630

-

PSU: Rosewill Lightning 800W Modular 80+ Gold

-

Monitor: 1920×1080 120Hz

-

Operating System: Windows 7 Ultimate 64-bit w/SP1

Results

As shown on the previous pages, the Nepton 280L was tested in a roof-mounted exhaust configuration. Note that the TD02 and H220 were tested in different orientations, so you can still expect to get a little more performance out of the Nepton if you desire. After struggling to clear some pockets of air out of the pump in the Swiftech H220 though, I now think twice about mounting radiators lower than the CPU…but that’s a story for another time (and you should have better luck with a completely sealed system).

A great showing as expected for the first 280mm radiator I’ve personally tested. It’s unfortunate I don’t have any natural competitors on hand, as I’d really want to see where the Nepton 280L differs from the other 280mm options. The performance is there, but this might be one of the products that I’d consider testing with some sort of a noise limit – those 140mm fans are powerful and move a lot of air (and a lot of noise as a result!). I don’t normally record any sort of sound pressure, as I believe the results are invalidated as soon as you place your cooler in a different case in a different room with different dimensions at a different distance from your ears. The noise was subdued quite a bit by the H630’s foam-lined panels, but this cooler really shines with a custom PWM profile – remember, I test all coolers without any fan controls (all fans at 100%), so the bar graph shows pure cooling performance with ambient temperature accounted for. It’s intended to show the maximum performance a cooler is capable of, it’s up to you to make sure your components allow the results you want with the noise level and installation you require.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Liquid Cooling Final Thoughts

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

The Nepton 280L is a solid option for someone looking to easily add some performance to a case with 140mm fan mounts. I think the overall design is subtle and attractive, and the included 140mm JetFlo fans are a force to be reckoned with. It may take some tuning to find a balance of performance and noise that is acceptable to you, but I appreciate that I get to determine that for myself. Overall, I think they’re a step up from most included stock fans.

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Cooler Master Nepton 280 Conclusion

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

While it doesn’t stray too far from the generic aluminum radiator and plastic water block AIO cooler formula, the overall design is pretty attractive. The white LED on the pump matches Cooler Master gear nicely, and the matte/gloss black themes allow the Nepton 280L to blend in with your setup instead of define it. It can’t match the metal finishes and accents on the Tundra series of coolers, but it’s pretty par for the course for the 280mm all in one coolers that are available.

The construction doesn’t approach that of a custom loop obviously, but the paint quality on the radiator is durable and the fan mounting threads are clean (a personal pet peeve of mine!). The mounting bracket and back plate are solid, and I don’t feel like the unit will spring a leak (a pretty important quality in a PC water cooler). The included screws and accessories are high-quality and substantial. I know some take issue with the FEP tubing, but as a non-porous material it’s not a bad choice for a completely closed system that isn’t supposed to be refilled.

It’s hard to rate the functionality of CPU coolers sometimes – they all cool the CPU, so they’re all pretty functional! It’s nice that Cooler Master added 120mm fan mounts to the radiator, as most users will be able to configure a push/pull setup with extra fans they have sitting around if they want (or if their case already contains exhaust fans, the Nepton 280L can just be mounted directly to them, space permitting). Otherwise, you’ll run into the same caveats as any other large radiator; just make sure you have the space to take advantage of the performance.

Value is the one area I cannot address at this time, because I’ve been unable to obtain any pricing details for the Nepton 280L. It isn’t available in retail channels yet, but I would expect it to be priced exactly at the level of the competition, with a possible premium for the JetFlo fans and the fact that it’s a brand new product. Wherever the price ends up, I’m willing to bet the Nepton 280L will offer the same value as other 280mm coolers. EDIT: While the Cooler Master Nepton 280L was originally intended to be priced at $119.99 MSRP, it appears to only be available for $139.99 (Newegg / Amazon) placing it right alongside the Kraken X60 at $139.99 and Corsair’s H110 at $129.99.

Honestly, the Nepton 280L doesn’t really break a lot of new ground – and that’s not really what it needs to do. Cooler Master didn’t have an answer to the competition’s 280mm water cooling units, and now they do – and the JetFlo fans are a step up from alternative stock options. If you’re looking for a liquid cooler to fill your twin 140mm fan mounts, the Nepton 280L is as good of a choice as any. I wouldn’t have a problem recommending this unit to my friends (especially for the easy installation!), but it really feels designed to offer an alternative solution so you don’t have to put a Corsair or NZXT cooler in your Cooler Master case. I can understand that, and I’m always glad to have options to choose from.

Pros:

+ 280mm of performance

+ Subdued design that blends in with most setups

+ Easier installation than the competition

+ 140mm JetFlos are a step up for stock fans

+ Thumbscrews!

+ Drilled for both 120/140mm fan configurations

Cons:

– Fans get loud at 100% (as most fans admittedly do…)

– Pump emits a whine at some RPMs

– Thumbscrews can interfere with dust filters in some cases

Ratings:

-

Performance: 8.50

-

Appearance: 8.25

-

Construction: 7.50

-

Functionality: 8.50

-

Value: 8.00

if ($script:h1count -eq $null) { $script:h1count = 0 }

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

Final Score: 8.15 out of 10.

$script:h1count++

if ($script:h1count -eq 2) { return “

” }

else { return $args[0].Value }

2 thoughts on “Cooler Master Nepton 280L Liquid CPU Cooler Review”

I have one of these 280L Neptons cooling a heavily OC’d A10 7850K and it is far and away the best AIO out there. I have thrown an obscene amount of voltage at it for OC’ing review purposes and it has easily taken it by scaling the excellent Jet Flo 140mm fans. I think the SP may be underrated for some reason. Thus far I have been using it in push only mode, but I am going to see what effect push /pull adds.

A very impressive unit to be sure.

Hey Greg, glad you enjoyed the review. The Nepton series certainly seem to be strong performers – you’ll have to check out Aidan’s review of a new Nepton cooler, as it seems to have fixed some of my noise complaints 🙂 Hard to beat those twin 140mm JetFlo fans though…

I’ve considered a Nepton for my A10-7850K as those things draw a surprising amount of power when overclocked! What do you have yours running at (and on what board)? I can’t seem to get mine completely stable above 4.6 GHz without pushing an uncomfortable amount of voltage. I’d be interested to hear if it’s just my chip (or board, for that matter) 🙂

Comments are closed.